-

Metal Cutting Saw Blades

The Menasa blades are an ideal choice for cutting metals, which require precision, strength, and durability, in all sectors of the metalworking industry, automotive or other sectors related to the cutting of solids, these blades will offer you superior results and reliable performance.

The Menasa circular blade with CERMET tipped teeth is a non-coated blade suitable for cutting solid sections in high-alloy steel on static machines. It is the best solution for applications aiming for maximum productivity.

Geometry

Angles and clearances designed to achieve the best finishing performance and ensure high productivity in terms of workpieces. The side relief angle reduces the effort and heat generation during cutting, making this type of blade particularly suitable for cutting high-carbon steels.

Teeth in Cermet

The cermet used on our blades is a composite material made up of a special mixture of ceramic oxides, where the ceramic matrix in the cermet structure gives the tooth a very high hardness and at the same time guarantees properties such as wear resistance, ideal to ensure the maximum performance of the Gallium blade.

Body

The bodies of the Menasa blades are made from special steels sourced from Japanese steel mills, which are hardened and tempered by Gallium. Cutting-edge construction methods allow the Menasa blades to achieve maximum levels of durability and cutting performance.

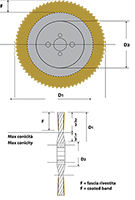

Run Out and Flatness

A Menasa blade body ensures very low deformation tolerances, thus providing high quality in terms of cutting finish and tool performance. A body that is not perfectly straight can cause vibration problems and premature blade wear.

-

Cut Off Circular Saw Blades

In HSS

Raw Materials

DMo5 is our standard steel.

Co5 should be used only to cut hard materials like stainless steels or high tension steels.

DMCo05 (0,5% Co) is a good alternative to the DMo5 because, due to the help of 0,5% cobalt, this entry level material give excellent perfomances on high speed cutting in particular if used with the BRAVO BLUE coating.

MCo2 (2% Co) is a great substitute to the Co5 (5% Co) when you want to cut hard materials but with a lower investment in the tool cost.HSS-DMo5 (M2)–DIN 1.3343–JIS SKH51 HSS

High Speed tungsten-molybdenum steel

HSS-Co5(M35)–DIN 1.3243–JIS SKH55–HSS-E

High Speed tungsten-molybdenum-cobalt steel

HSS-DMCo05(Co 0,5%)–DMO5–DM05

High Speed tungsten-molybdenum-cobalt steel

HSS-MCo2(Co 2%) –MCO–HSS-E–M2Co

High Speed tungsten-molybdenum-cobalt steelCutting & Feed Speeds

It is essential that the rotation speed and feed speed (when automatic machines are involved) should be under control in order to optimise the cutting process. There is in fact a close relationship between the two speeds (rotation and feed) which must always be observed. In the table below, obtained from experimental data, we recom-mend the most suitable Cutting speed (V) and Feed/tooth (Az) values, according to the material to be cut.

-

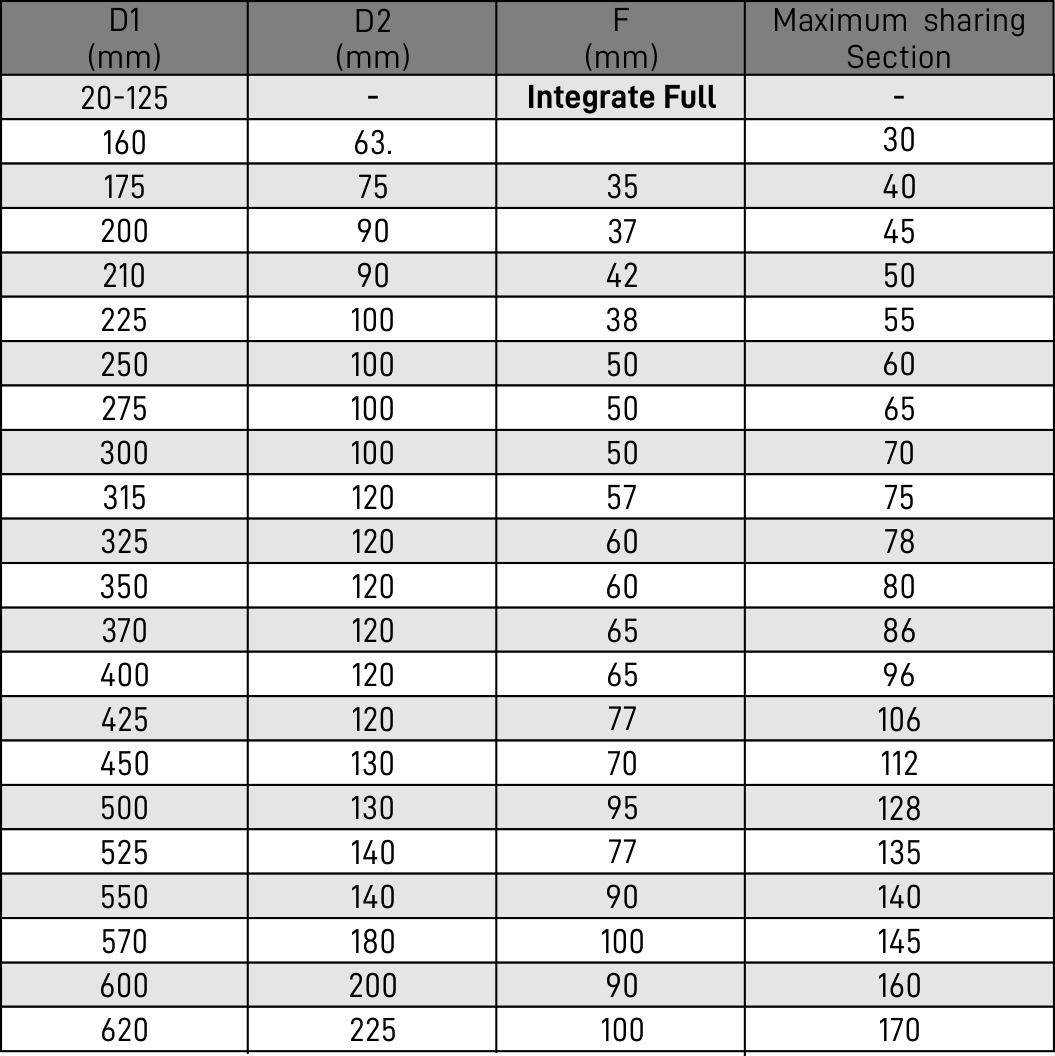

HSS Circular Saw Blades

Menasa can supply circular saws in high speed steel (5% molybdenum content) suitable for cutting-off steels and alloys with tensile strength betwe-en 500 N/mm² and 800 N/mm². The saw blades are used on manual, semi-automatic and fully automatic sawing machines to cut tubes and pipes, open sections and solid sections up to 200 mm. Our range goes from Ø 160 mm to Ø 620 mm, with thicknesses from a minimum of 1 mm to a maximum of 6 mm by variable incre-ments, with tooth forms A - AW - B - BW - C - BR (chip breaker). The standard execution of the whole range is HP-GRIND; we also supply CO² steam treated blades and PVD (Physical Vapour Deposition) coated ones.

Coating Brands

HSS-DMo5

Circular saws in super high speed steel (5% co-balt content) suitable for cutting-off steels and alloys with tensile strength above 800 N/mm². The saw blades are used on semi-automatic and fully automatic sawing machines to cut tubes and pipes, open sections and olid sections up to 200 mm.

-

TCT Circular Saw Blades

HM carbide tipped circular saws suitable for cutting steel solids or profiles with big wall thickness.The special patented tooth form allows these special blades to drastically reduce the cutting times and improves the surface finishing if used on the right machine.Our range covers different diameters from 250 mm to 315 mm with a central bore of 32 and 4/9/50 pinholes or diameters from 360 to 460 mm with central bore 50 mm and 4/16/80 pinholes. Also available with cermet toothing or TiN coated.